Tin/Lead Plating

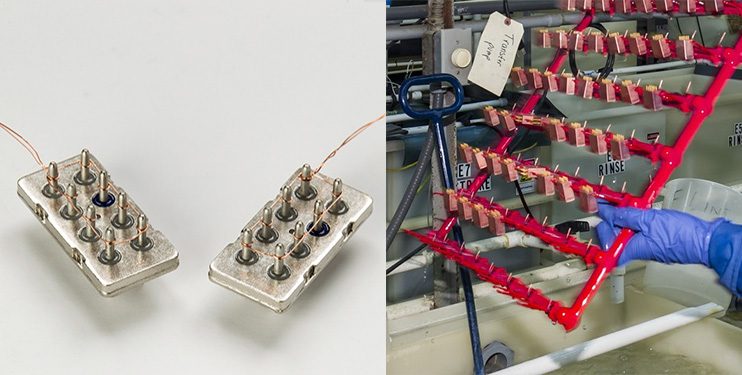

Tin/lead alloy electroplating is best used to facilitate soldering, protect against corrosion and create a ductile surface. WPC can provide tin/lead alloy plating as 60/40 or 90/10 compositions in either dull/matte or lustrous bright finishes for functional engineering and industrial applications. WPC has a wealth of knowledge in the tin/lead plating industry for electrical components and specifically for finished relay assemblies.

The co-deposition of lead with tin is used extensively for the prevention of tin whisker growth. WPC can utilize other plated metals such as nickel or copper as an undercoat for tin to assist with adhesion and electrical properties.

WPC has a significant production system of plating baths, equipment, and personnel devoted to tin/lead plating. Let WPC work with you to determine your tin/lead plating needs.

When considering tin plating for your product, please determine and convey:

- Classification, appearance and composition of tin and lead

- Type and nature of the substrate base metal (i.e., high strength steel will tell us that it is susceptible to hydrogen embrittlement and may require post-plate baking)

- Plating thickness range and possibly where is the most important surface location of desired thickness

- Significant surfaces

- Required undercoats or strike layers

- Any specific testing required to the plated deposit

- Is tin whisker growth not a possible concern? Has tin plating been considered as a replacement? WPC has tin plating available.

- Is RoHS compliance is required? Tin/Lead plating is assumed to not meet the requirements of RoHS. Without a deviation authorization for RoHS, a compliant plating maybe required.

- Has tin plating been considered as a replacement? WPC has RoHS compliant tin plating available.

- Please convey if the part must be rack or barrel plated if you have already determined this

Specifications for Tin/Lead Plating:

- MIL-P-81728

- AMS-P-81728 (specify dull, bright and composition)

- ASTM B579-73 (specify dull, bright and composition)

WPC does not offer hot dip, reflow or flow-brightened tin deposit